Presentations by Ghazaleh and Dr. Najafi during in-person group meeting

During our group meeting on Thursday February 2, 2023, Ghazaleh Mozaffari, a PhD student of BBRG group, and Dr. Gholamhassan Najafi, a visiting professor from Iran made presentations.

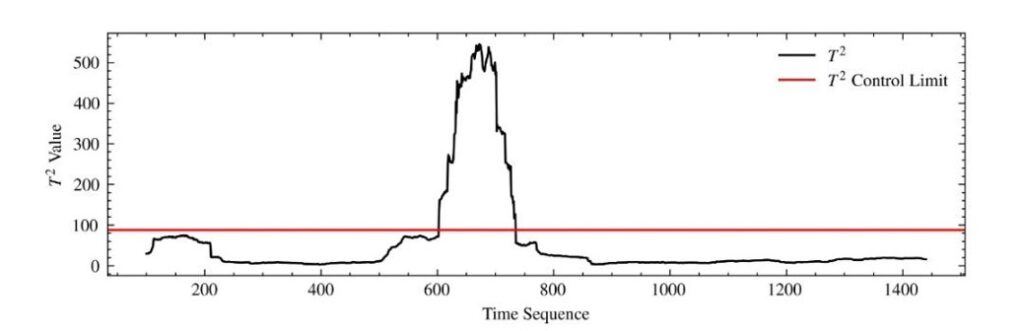

Ghazaleh presented on Fault Detection of the Takachar Bio-reactor using Machine Learning Algorithms. Her presentation abstract is as follow. More than 4 billion tons/year of biomass residues in rural communities are burned in open air. It is not only a significant economic waste ($120 billion/year), but it also contributes to toxic air pollution and life-destroying wildfires in many parts of the world. Takachar bioreactor can convert waste biomass into solid fuel, fertilizer, and other bioproducts based on a novel thermochemical process called oxygen-lean torrefaction. Comparing to the process of sending waste biomass to centralized conversion facilities, Takachar’s system is more economically and environmentally effective by significantly reducing the logistics costs and fuel consumption. There are some unexpected tripping events inside the reactor which may leads to long downtime and lower efficiency of the process. In this project, our aim is to early detect tripping events to minimize downtime and ensure that the system is operating effectively and safely. The graph below shows an example of a tripping event detection. Many factors can be involved in this fault, such as type and composition of feedstock, reactor configurations, operating temperature, etc. Due to the large number of variables and nonlinear behavior of the process, model-based fault detection techniques would be insufficient. Therefore, we try to apply machine learning algorithms to time-dependent data of the reactor to analyze the faults.

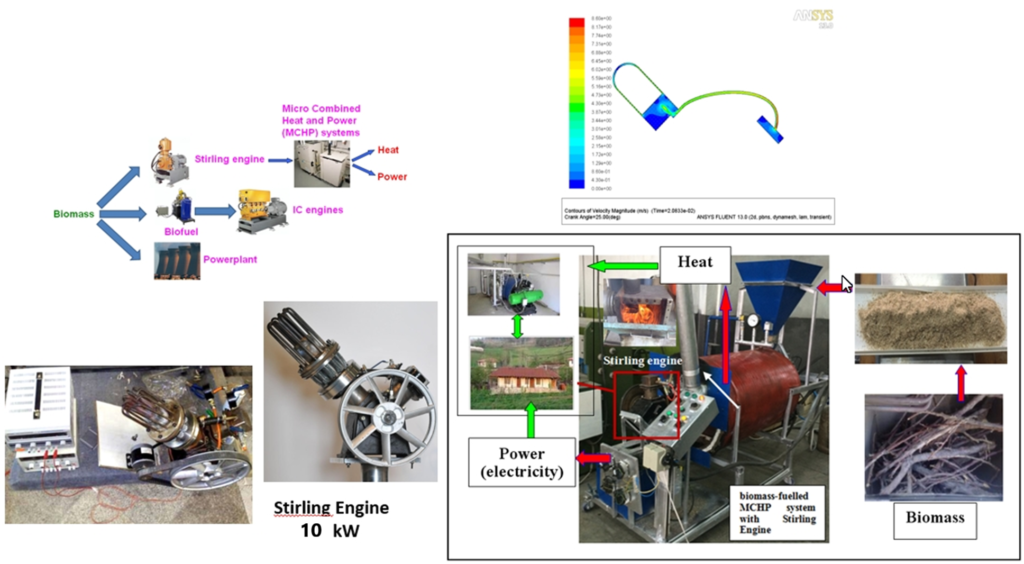

Dr. Gholamhassan Najafi presented on Combustion of biomass at burner and CHP systems. His presentation abstract is as follows. Biomass is one of the important renewable energy sources. Biomass fuels exhibit a range of chemical and physical properties, particularly size and shape. Heat and Mass transfer of biomass flame in burner has been investigated experimentally and has been verified by simulation results. The aim of this project is to develop and test an experimental setup for the stabilization of hybrid turbulent flames of micron sized biomass powder suspended in air mixtures. This setup should enable further research on biomass dust combustion and investigate the scalability of biomass dust flames. The equivalence ratio could only be controlled to a limited extent. Spherical biomass powder particle ranging in size from 10 µm to 20 mm is dispersed using a mixture of air. Flame speeds are measured using particle image velocimetry (PIV), while flame temperatures are determined using thermocouples. Biomass particles underwent two combustion phases: the volatile matter and fixed carbon combustion phases, which correspond to homogeneous and heterogeneous reactions, respectively. Throughout the burning phase, there were two peak values of the combustion temperature, 1100 and 1600 °C, which appeared in the volatile matter and fixed carbon combustion phase, respectively. A typical mCHP (micro combined heat and power) system was integrated by gamma type Stirling engine to meet electric, heating and hot water demands. The combustion test results, which is a key technology for small and micro scale mCHP systems have been presented and the combustion parameters for the Gamma type Stirling engine power system are discussed. The effect of sawdust biomass fuel on mCHP system emissions (such as CO, NOx, HC) have investigated. The test results confirm the fact that Stirling engines that are driven by the temperature of biomass gases are able to achieve a valuable output power. Also, Analysis of pollutants showed that by increasing of sawdust mass flow rate from 0 to 0.14 (g/s), CO emissions increased 164 vol%, also HC and NOx emissions increased 295–24 ppm respectively. The test results confirmed that Stirling engines driven by the biomass gases are able to achieve a valuable output power. The highest efficiency was achieved when using sawdust biomass and the lowest was achieved when using pruned wood due to the difference in their gas heating values. The total efficiency varies between 78% and 90%.